Legacy Connection - Actuators

Signal system using the Manufacturing Service Bus

We present a signalling system, which is connted and controlled via the Manufacturing Service Bus (MSB). In this scenario manual turns of a knob are sensed digitally, processed in the MSB, and transmitted to a smart signal column to display a defined machine state.

Connecting components using the Manufacturing Service Bus (MSB)

The Manufacturing Service Bus provides a base for interconnecting various devices and sensors independent of utilized data transmission protocols.

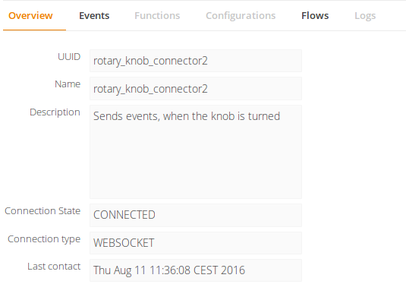

Digitalization of the knob movement is accomplished using a Raspberry Pi Microcomputer. This makes data exchange with the MSB possible without a lot of effort.

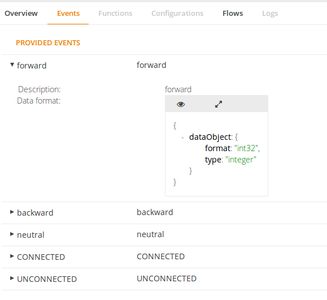

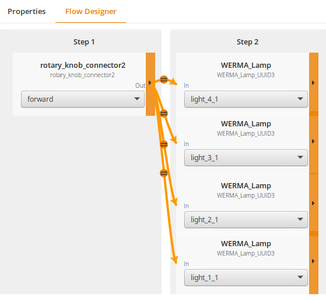

The MSB client library on the Microcomputer transmits events of different types (forward, backward, neutral), which can call functions provided by the signal column.

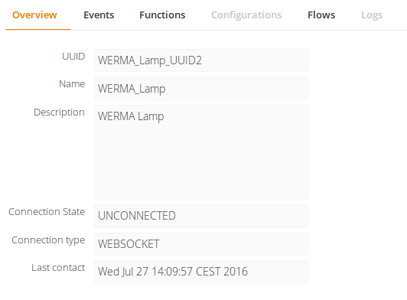

The WERMA WIN-Master module is connected to the MSB via websocket connection and provides functions for signal column control. Via an "Integration Flow" events can be "taught" to call functions.

Conclusion:

The Manufacturing Service Bus lets clients connect devices of various manufacturers without the need of complex integration. Furthermore the workflow is editable at any time and adaptable to changing requirements.

As an example, it would be possible to integrate a function to broadcast notification mails in reaction to specific events with minimal effort.

Used hardware: