Smart Scale

Application Center at Fraunhofer IPA Stuttgart

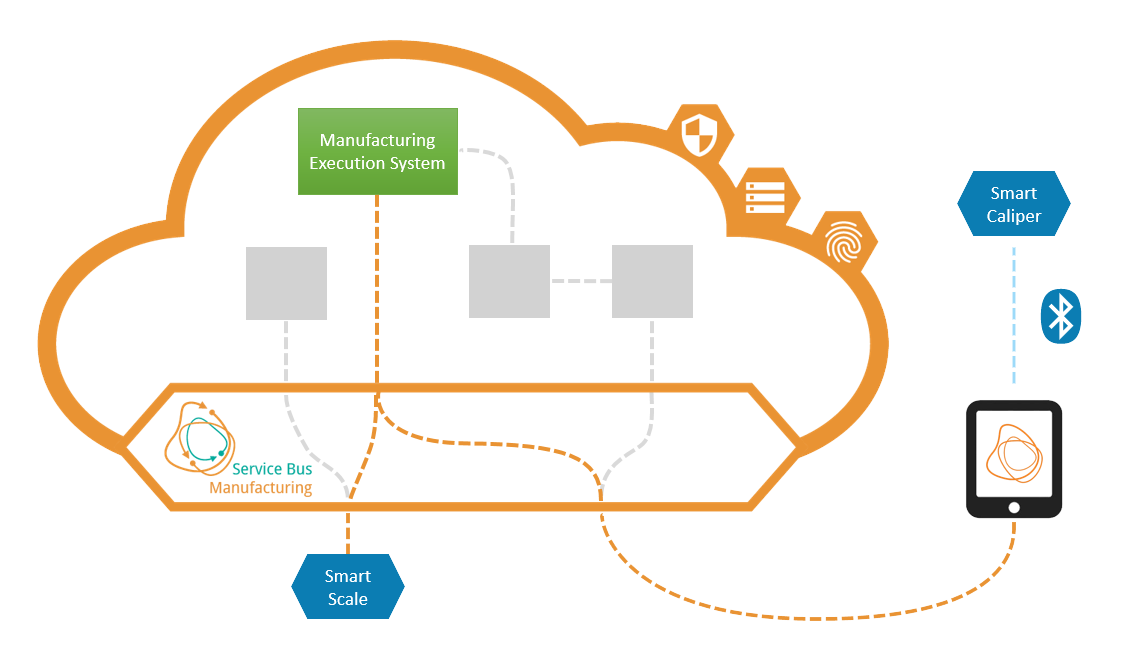

Together with the Future Work Lab from Fraunhofer IPA, Virtual Fort Knox has established central measuring system. It provides users with the ability to quickly and accurately collect data for work piece evaluation. Traditionally that type of data is collected manually and digitized at a later time. The cloud enabled system automatically transfers data to digital services which in turn use it for business processes or archiving.

Process:

A small software service was built for each device to dispatch measurements to the Manufacturing Service Bus (MSB)

The MSB is able to automatically relay the data to subscribed services. If, for example, a Manufacturing Execution System (MES) is in use, measurements can be considered for production supervision and process control. Configuration is done via Integration Flows using the easy to use MSB graphical user interface.

Advantages:

- Cloud connectivity of a readily available device, no specialized hardware necessary

- Easy collection of measured data using the Manufacturing Service Bus

- Error prevention by automatic capture of measurements

Hardware and software used in the scale demonstrator:

- Precision scale Ohaus Navigator NV

- Internet Interface for Ohaus Waage NV

- Additional software service (developed in Java)

Hardware and software used in the caliper demonstrator:

- Sylvac S_Cal EVO Bluetooth caliper

- Nexus 7 Tablet

- Additional software service (Smart Caliper App, developed in Android Studio)